Are you looking to optimise the procurement and picking process for Dual Source parts from an EWM-managed warehouse?

Managing dual-source parts can be difficult in fixed bins in the warehouse. Additionally, storage and retrieval of parts from fixed bins can be challenging if the parts have multiple pack sizes. It can result in Partial picking and exception handling which impacts the overall efficiency and productivity of the warehouse.

This case study is to provide an overview of how to efficiently manage dual-source parts with multiple pack sizes in a warehouse fixed bin. This will ultimately make your supply chain more efficient, cost-effective and resilient.

Process steps

Dual-source parts and different Pack sizes presents some challenges in the warehousing processes. All of these points must be considered for the process to go smoothly:

- Products are procured from more than one supplier

- Each supplier supplies products with different box quantity

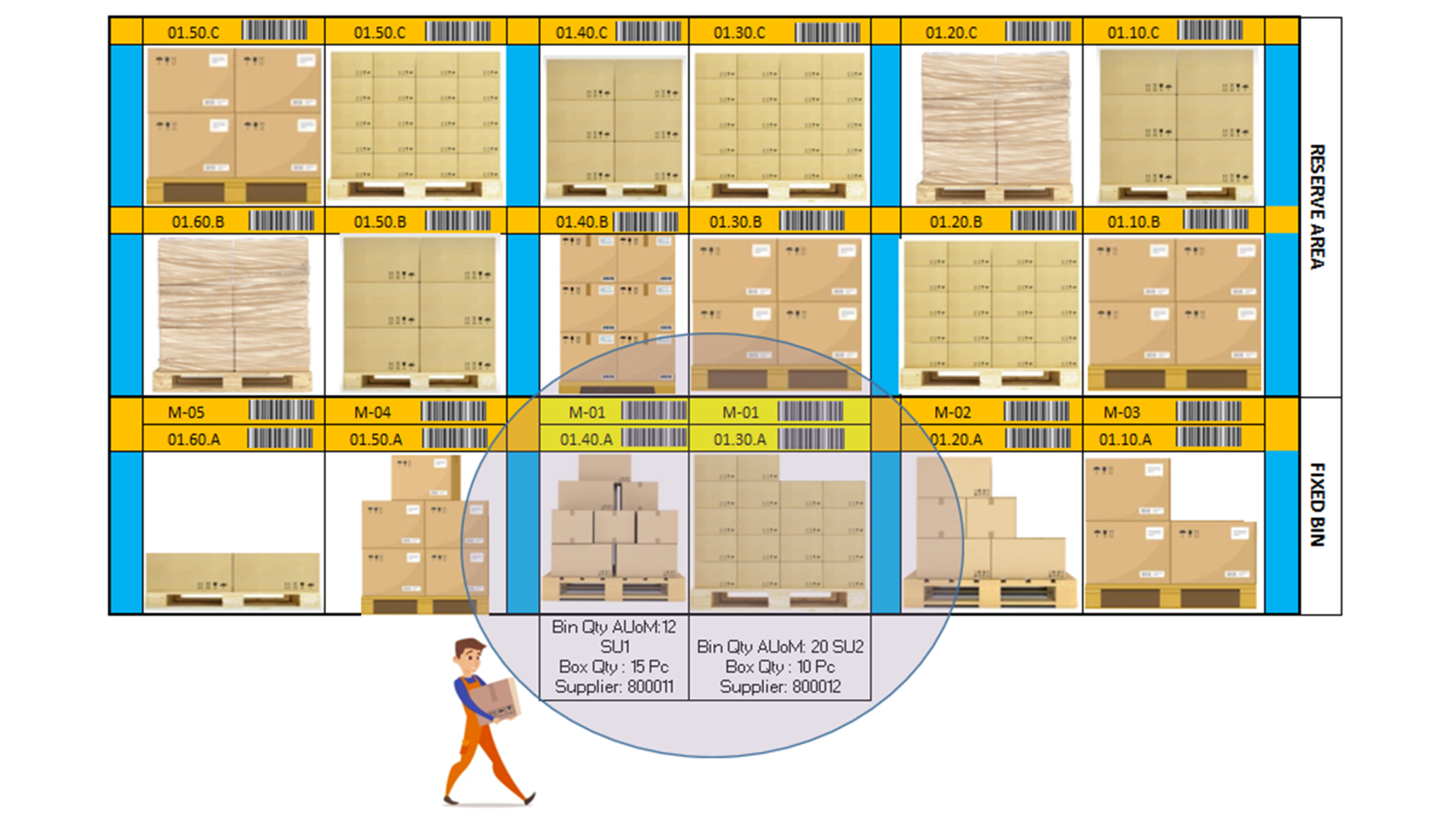

- Products are received into Pallets and are stored in Rack storage in the Warehouse

- Replenishment is executed from Reserve Rack Storage to the fixed bin

- Handling units are not used in fixed bin storage, or Storage of nested Handling units can complicate the picking process from fixed Bin storage

- Picking is carried out from the fixed bin in the Warehouse

- Production Pick request quantity or the STO/Customer Outbound delivery quantity is not in multiples of box quantity

- Over-picking can be allowed within permissible tolerance limit to allow rounding of box quantity

Challenges

Dual Sourced parts have different box sizes, as they are specific to each supplier. This can cause below issues during MRP planning and Warehouse picking, if not managed correctly.

1. MRP is generating requirements based on quota and material master rounding Value. Procurement team to manually update Purchase order quantities based on supplier pack quantity (or box quantity).

2. Fixed Bin Storage does not store the box quantity. Warehouse pick quantity is not in multiples of box quantity. During picking execution, the picker picks the requested quantity following the below approach:

- The picker needs to physically open/break the box for picking partial quantities

Or

- Picker has to manually intervene and adjust the requested quantity by declaring exception during pick execution

Picking partial box quantity is not desirable as it requires counting which can slow down the picking process. Manually adjusting pick quantity to box quantity by picker the requires additional expertise and is recommended only in exceptional scenarios. Both approaches can result in human errors too.

These approaches have a significant impact on warehouse operations and the end-to-end supply chain.

3. Nested Handling units can be used as a possible solution for rounding the pick quantity to multiples of Box Handling units. However, this complicates the stock management of fixed bins. It requires additional labels at box level and an additional step during picking to confirm the box Handling unit to be picked.

4. The system does not store box quantities. Hence, it is difficult to track boxes in stock and round pick warehouse tasks in multiple box quantity.